- Project

- Fluid Tubes

- Fluid Shell

- Heat Balance

- Geometry

- Baffles

- Overall Calculation

- Mechanical Calculation

- Batch

- Graphs

- Reports

- Menu

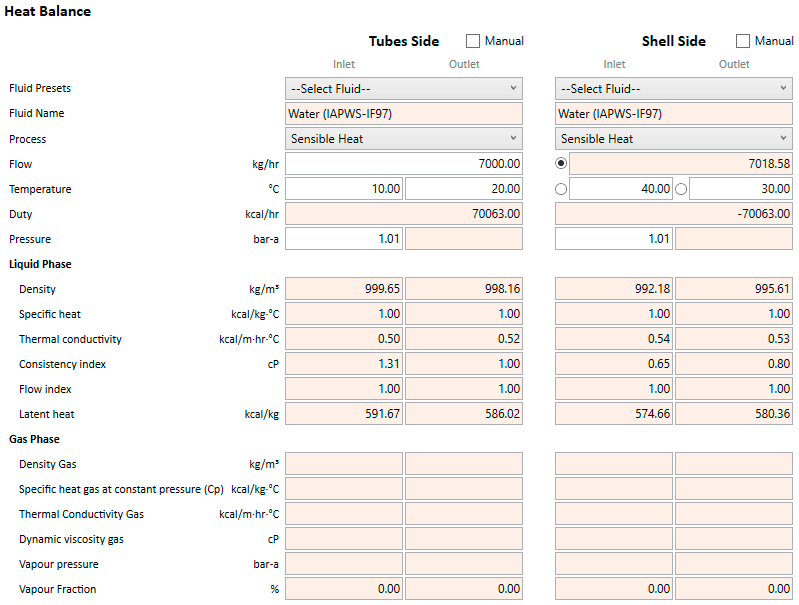

Heat Balance

Form Fields

These are the fields and UI elements that are shown in this form, along with a describing text and explanation about their usage in the application.

Executes the heat balance calculation for the defined data. Each execution of this method counts as an API call in your license. When the server returns the resulting data, they are shown along with any warning/error message that might have appeared. The background of the application will change and give you a quick hint about the result of your calculation:

Calculation ended successfully

Calculation ended with warnings

Calculation was not finished due to errors

Performs a swap of the fluids from tubes to shell and vice-versa. This is performed for the fluid data-tables at the bottom of the page and also for any value in the Heat Balance section of the page (i.e. flow, temperatures, duty, densities, specific heats, etc).

Declares the flow direction to be counter current, meaning that the fluid in the shell and the tubes go in opposite directions: The shell inlet is at the same side of the heat exchanger as the tubes outlet. Simmilarly, the shell outlet is at the same side as the tubes inlet.

Declares the flow direction to be co-current, meaning that the fluid in the shell and the tubes flow towards the same direction: The shell inlet is at the same side of the heat exchanger as the tubes inlet. Simmilarly, the shell outlet is at the same side as the tubes outlet.

Heat Balance

Tube Side

Shell Side

When the tubes fluid is set to manual, all its read-only fields of temperatures, duties, densities, specific heats, etc. in the Heat Balance section turn writable. The user has the option then to manually set the values for those (all are required) for the given inlet and outlet temperatures (both required too). When in manual mode, the values in the Fluid Properties section are ignored (particularly values in the data-table), and only those defined in the Heat Balance section are used.

This mode can be used in what-if scenarios, if the user wants to test changes in the fluid properties, without having to define a whole new fluid. It can also be used when a fluid is not very well defined and its physical properties are only known for one or two different temperatures. In that case defining a new fluid resource with only one or two temperatures would be equivalent to enter those very same values into the Heat Balance section directly and not use any fluid at all (empty, new fluid).

It is always recommended to give the fluid a name, even when manual calculation mode is active, since that field will be used in reports, the project summary, etc.

When the shell fluid is set to manual, all its read-only fields of temperatures, duties, densities, specific heats, etc. in the Heat Balance section turn writable. The user has the option then to manually set the values for those (all are required) for the given inlet and outlet temperatures (both required too). When in manual mode, the values in the Fluid Properties section are ignored (particularly values in the data-table), and only those defined in the Heat Balance section are used.

This mode can be used in what-if scenarios, if the user wants to test changes in the fluid properties, without having to define a whole new fluid. It can also be used when a fluid is not very well defined and its physical properties are only known for one or two different temperatures. In that case defining a new fluid resource with only one or two temperatures would be equivalent to enter those very same values into the Heat Balance section directly and not use any fluid at all (empty, new fluid).

It is always recommended to give the fluid a name, even when manual calculation mode is active, since that field will be used in reports, the project summary, etc.

Inlet

Outlet

Inlet

Outlet

This is a dropdown list of fluids for quick access to be used in the tubes side. The user can set up the fluids in this list through the Tools → Select Presets → Fluid Presets menu. A single set of fluids can be selected for both the tubes side and the shell side. The same list of preset fluids will be available for both sides. The user can ellaborate this list from the public shared fluids database and from any other fluid with read access (either self-owned or readable through a group).

This is a dropdown list of fluids for quick access to be used in the shell side. The user can set up the fluids in this list through the Tools → Select Presets → Fluid Presets menu. A single set of fluids can be selected for both the tubes side and the shell side. The same list of preset fluids will be available for both sides. The user can ellaborate this list from the public shared fluids database and from any other fluid with read access (either self-owned or readable through a group).

Used to select the type of heat transfer that will occurr in the tube side:

- Sensible Heat: To be selected when changes of tubes fluid temperature imply no change in phase.

- Condensation: To be used when there is a phase change in the tubes fluid. Please note that condensation can only occurr in one side of the heat exchanger at a given time. An error will be returned when a calculation with condensation in both sides is attempted. In order for a fluid to be elegible to be used for condensation it must be marked with the steam behaviour checkbox and its molar mass be defined.

Used to select the type of heat transfer that will occurr in the shell side:

- Sensible Heat: To be selected when changes of shell fluid temperature imply no change in phase.

- Condensation: To be used when there is a phase change in the shell fluid. Please note that condensation can only occurr in one side of the heat exchanger at a given time. An error will be returned when a calculation with condensation in both sides is attempted. In order for a fluid to be elegible to be used for condensation it must be marked with the steam behaviour checkbox and its molar mass be defined.

Mass flow rate of the fluid in the tubes side. Please note that, strictly speaking, in whatever chosen measurement system, seconds should be used. The application uses hours (hr) instead of seconds just for user's convenience however. Required.

- Metric: kg/hr

- SI: kg/hr

- British: lb/hr

To be selected when the free parameter is the shell flow.

Mass flow rate of the fluid in the shell side. Please note that, strictly speaking, in whatever chosen measurement system, seconds should be used. The application uses hours (hr) instead of seconds just for user's convenience however. Calculated when it is the free parameter. Required otherwise.

- Metric: kg/hr

- SI: kg/hr

- British: lb/hr

Bulk inlet Temperature of the fluid in the tubes side. Required.

- Metric: °C

- SI: °C

- British: °F

Bulk outlet Temperature of the fluid in the tubes side. Required.

- Metric: °C

- SI: °C

- British: °F

To be selected when the free parameter is the shell inlet temp.

Bulk inlet Temperature of the fluid in the shell side. Calculated when it is the free parameter. Required otherwise.

- Metric: °C

- SI: °C

- British: °F

To be selected when the free parameter is the shell outlet temp.

Bulk outlet Temperature of the fluid in the shell side. Calculated when it is the free parameter. Required otherwise.

- Metric: °C

- SI: °C

- British: °F

Duty, or Power, as the amount of energy transferred per unit time, calculated in the tubes side. Due to the Law of Conservation of Energy, this calculated value will be equal, but with opposite sign, to the Shell: Duty value.

- Metric: kcal/hr

- SI: kW

- British: BTU/hr

Duty, or Power, as the amount of energy transferred per unit time, calculated in the shell side. Due to the Law of Conservation of Energy, this calculated value will be equal, but with opposite sign, to the Tubes: Duty value.

- Metric: kcal/hr

- SI: kW

- British: BTU/hr

Pressure of the fluid in the tubes, calculated/known at its bulk inlet temperature.

- Metric: bar-a

- SI: bar-a

- British: psi-a

Density of the fluid in the tubes, calculated at its bulk outlet temperature. It can only be calculated after the Overall Calculation has finished, since the Geometry is needed to calculate the pressure drop.

- Metric: bar-a

- SI: bar-a

- British: psi-a

Pressure of the fluid in the shell, calculated/known at its bulk inlet temperature.

- Metric: bar-a

- SI: bar-a

- British: psi-a

Pressure of the fluid in the shell, calculated at its bulk outlet temperature. It can only be calculated after the Overall Calculation has finished, since the Geometry is needed to calculate the pressure drop.

- Metric: bar-a

- SI: bar-a

- British: psi-a

Liquid Phase

Density of the fluid in the tubes, calculated at its bulk inlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Density of the fluid in the tubes, calculated at its bulk outlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Density of the fluid in the shell, calculated at its bulk inlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Density of the fluid in the shell, calculated at its bulk outlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Specific Heat of the fluid in the tubes, calculated at its bulk inlet temperature. By definition, it is the amount of heat needed to raise the temperature of one kilogram of mass by 1 kelvin.

- Metric: kcal/kg·°C

- SI: kJ/kg·°C

- British: BTU/lb·°F

Specific Heat of the fluid in the tubes, calculated at its bulk outlet temperature. By definition, it is the amount of heat needed to raise the temperature of one kilogram of mass by 1 kelvin.

- Metric: kcal/kg·°C

- SI: kJ/kg·°C

- British: BTU/lb·°F

Specific Heat of the fluid in the shell, calculated at its bulk inlet temperature. By definition, it is the amount of heat needed to raise the temperature of one kilogram of mass by 1 kelvin.

- Metric: kcal/kg·°C

- SI: kJ/kg·°C

- British: BTU/lb·°F

Specific Heat of the fluid in the shell, calculated at its bulk outlet temperature. By definition, it is the amount of heat needed to raise the temperature of one kilogram of mass by 1 kelvin.

- Metric: kcal/kg·°C

- SI: kJ/kg·°C

- British: BTU/lb·°F

Thermal Conductivity of the fluid in the tubes, calculated at its bulk inlet temperature. It measures the capacity of the fluid (liquid) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the tubes, calculated at its bulk outlet temperature. It measures the capacity of the fluid (liquid) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the shell, calculated at its bulk inlet temperature. It measures the capacity of the fluid (liquid) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the shell, calculated at its bulk outlet temperature. It measures the capacity of the fluid (liquid) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Consistency Index of the fluid in the tubes, calculated at its bulk inlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Consistency Index of the fluid in the tubes, calculated at its bulk outlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Consistency Index of the fluid in the shell, calculated at its bulk inlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Consistency Index of the fluid in the shell, calculated at its bulk outlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Flow Behaviour Index (dimensionless) of the fluid in the tubes, calculated at its bulk inlet temperature. It will be 1 for Newtonial fluids and <1 for pseudoplastic fluids. Values >1 as less common and are found in dilatant fluids.

Flow Behaviour Index (dimensionless) of the fluid in the tubes, calculated at its bulk outlet temperature. It will be 1 for Newtonial fluids and <1 for pseudoplastic fluids. Values >1 as less common and are found in dilatant fluids.

Flow Behaviour Index (dimensionless) of the fluid in the shell, calculated at its bulk inlet temperature. It will be 1 for Newtonial fluids and <1 for pseudoplastic fluids. Values >1 as less common and are found in dilatant fluids.

Flow Behaviour Index (dimensionless) of the fluid in the shell, calculated at its bulk outlet temperature. It will be 1 for Newtonial fluids and <1 for pseudoplastic fluids. Values >1 as less common and are found in dilatant fluids.

Latent Heat of the fluid in the tubes, calculated at its bulk inlet temperature. It measures the thermal energy released or absorbed by the fluid, during a constant-temperature process - usually a first-order phase transition (condensation). It can be understood as heat energy in hidden form which is supplied or extracted to change the state of the fluid without changing its temperature. See also Enthalpy of vaporization.

- Metric: kcal/kg

- SI: J/kg

- British: BUT/lb

Latent Heat of the fluid in the tubes, calculated at its bulk outlet temperature. It measures the thermal energy released or absorbed by the fluid, during a constant-temperature process - usually a first-order phase transition (condensation). It can be understood as heat energy in hidden form which is supplied or extracted to change the state of the fluid without changing its temperature. See also Enthalpy of vaporization.

- Metric: kcal/kg

- SI: J/kg

- British: BUT/lb

Latent Heat of the fluid in the shell, calculated at its bulk inlet temperature. It measures the thermal energy released or absorbed by the fluid, during a constant-temperature process - usually a first-order phase transition (condensation). It can be understood as heat energy in hidden form which is supplied or extracted to change the state of the fluid without changing its temperature. See also Enthalpy of vaporization.

- Metric: kcal/kg

- SI: J/kg

- British: BUT/lb

Latent Heat of the fluid in the shell, calculated at its bulk outlet temperature. It measures the thermal energy released or absorbed by the fluid, during a constant-temperature process - usually a first-order phase transition (condensation). It can be understood as heat energy in hidden form which is supplied or extracted to change the state of the fluid without changing its temperature. See also Enthalpy of vaporization.

- Metric: kcal/kg

- SI: J/kg

- British: BUT/lb

Gas Phase

Gas Density of the fluid in the tubes, calculated at its bulk inlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Gas Density of the fluid in the tubes, calculated at its bulk outlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Gas Density of the fluid in the shell, calculated at its bulk inlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Gas Density of the fluid in the shell, calculated at its bulk outlet temperature.

- Metric: kg/m3

- SI: kg/m3

- British: lb/ft3

Specific Heat of the fluid in the tubes held at constant pressure (Cp), calculated at its bulk inlet temperature.

- Metric: kcal/kg·ºC

- SI: kJ/kg·ºC

- British: BTU/lb·ºF

Specific Heat of the fluid in the tubes held at constant pressure (Cp), calculated at its bulk outlet temperature.

- Metric: kcal/kg·ºC

- SI: kJ/kg·ºC

- British: BTU/lb·ºF

Specific Heat of the fluid in the shell held at constant pressure (Cp), calculated at its bulk inlet temperature.

- Metric: kcal/kg·ºC

- SI: kJ/kg·ºC

- British: BTU/lb·ºF

Specific Heat of the fluid in the shell held at constant pressure (Cp), calculated at its bulk outlet temperature.

- Metric: kcal/kg·ºC

- SI: kJ/kg·ºC

- British: BTU/lb·ºF

Thermal Conductivity of the fluid in the tubes, calculated at its bulk inlet temperature. It measures the capacity of the fluid (gas) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the tubes, calculated at its bulk outlet temperature. It measures the capacity of the fluid (gas) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the shell, calculated at its bulk inlet temperature. It measures the capacity of the fluid (gas) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Thermal Conductivity of the fluid in the shell, calculated at its bulk outlet temperature. It measures the capacity of the fluid (gas) to conduct heat.

- Metric: kcal/m·hr·°C

- SI: W/m·°C

- British: BTU/ft·hr·°F

Dynamic Viscosity of the fluid (as a gas) in the tubes, calculated at its bulk inlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Dynamic Viscosity of the fluid (as a gas) in the tubes, calculated at its bulk outlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Dynamic Viscosity of the fluid (as a gas) in the shell, calculated at its bulk inlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Dynamic Viscosity of the fluid (as a gas) in the shell, calculated at its bulk outlet temperature. This magnitude expresses the resistance to shearing flows, where adjacent layers move parallel to each other with different speeds.

- Metric: cP

- SI: cP

- British: cP

Vapour Pressure of the fluid in the tubes, calculated at its bulk inlet temperature. The equilibrium vapor pressure is an indication of a liquid's evaporation rate. Higher values are shown in more volatile fluids.

- Metric: bar

- SI: bar

- British: psi

Vapour Pressure of the fluid in the tubes, calculated at its bulk outlet temperature. The equilibrium vapor pressure is an indication of a liquid's evaporation rate. Higher values are shown in more volatile fluids.

- Metric: bar

- SI: bar

- British: psi

Vapour Pressure of the fluid in the shell, calculated at its bulk inlet temperature. The equilibrium vapor pressure is an indication of a liquid's evaporation rate. Higher values are shown in more volatile fluids.

- Metric: bar

- SI: bar

- British: psi

Vapour Pressure of the fluid in the shell, calculated at its bulk outlet temperature. The equilibrium vapor pressure is an indication of a liquid's evaporation rate. Higher values are shown in more volatile fluids.

- Metric: bar

- SI: bar

- British: psi

Measures the portion of the fluid mass in the tubes which is in a vapour state at its bulk inlet temperature: When it is 0, the fluid is fully liquid. When it is 1, there is no liquid part and the fluid behaves completely as a gas. See also Vapour quality.

- Metric: %

- SI: %

- British: %

Measures the portion of the fluid mass in the tubes which is in a vapour state at its bulk outlet temperature: When it is 0, the fluid is fully liquid. When it is 1, there is no liquid part and the fluid behaves completely as a gas. See also Vapour quality.

- Metric: %

- SI: %

- British: %

Measures the portion of the fluid mass in the shell which is in a vapour state at its bulk inlet temperature: When it is 0, the fluid is fully liquid. When it is 1, there is no liquid part and the fluid behaves completely as a gas. See also Vapour quality.

- Metric: %

- SI: %

- British: %

Measures the portion of the fluid mass in the shell which is in a vapour state at its bulk outlet temperature: When it is 0, the fluid is fully liquid. When it is 1, there is no liquid part and the fluid behaves completely as a gas. See also Vapour quality.

- Metric: %

- SI: %

- British: %